Best practices for digital construction

It’s no secret that digital innovations can improve productivity and help the construction industry navigate disruptions and mitigate risks. And in the wake of the COVID-19 pandemic, many project owners have been forced to step up their use of technology to enable their teams to work and collaborate remotely.

But beyond the context of the current crisis, adoption of digital innovations has been slow. This delay is at least partly due to a lack of digital standards and experience within the industry. In addition, many players likely anticipate high up-front costs and a long wait before their investment pays off. Project owners are understandably wary of testing new digital tools on multibillion-dollar projects. And given that project success typically hinges on collaboration, introducing new digital workflows which may be unfamiliar to some of the parties involved can seem daunting.

But the benefits can be greater and the barriers lower than many industry players expect. In the design phase, a fully digital construction project can reduce drawing revisions, redundant conversations, and version errors while lowering project risk and facilitating clash detection. Going digital also supports procurement across work packages and over time, increasing safety standards and allowing better workforce planning and machinery use. Of course, achieving these benefits requires parties to be willing to explore new solutions and fundamentally shift the way projects operate.

So when it came time to add a building to the McKinsey Digital Capability Center in Venice an almost unique opportunity for us to build a project from the ground up we chose to take our own medicine. Together with our partners on the project, we decided to roll out core digital tools, build the required capabilities, and push the boundaries of what is possible: exploring new ground to see for ourselves (and for the industry) what these tools and a new way of working can do.

Although we are still in the early stages of construction, a number of unforeseen challenges have already shown us how quickly digital tools can improve collaboration among stakeholders. These challenges, and the ones that will surely follow, will allow us to better understand the benefits of digital tools in construction and to empathize with companies facing these hurdles. We plan to share everything about our process good and bad so that construction leaders who are starting their digital-transformation journeys can take our lessons to heart and capture all of the value on offer.

Three pillars of digital construction

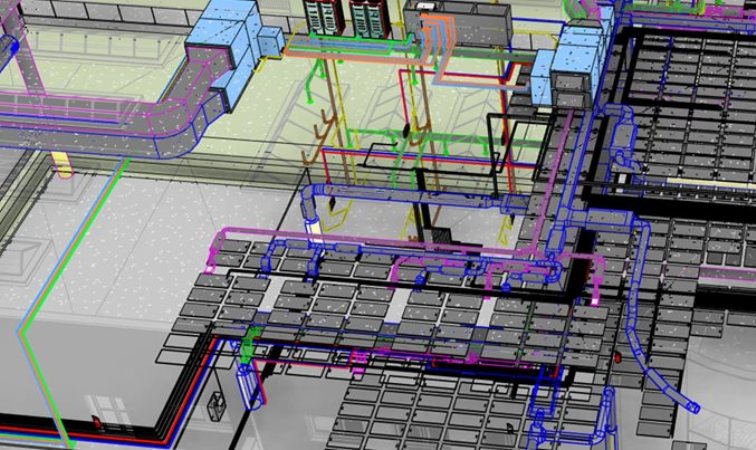

The entirety of our new building was designed using a building-information-modeling (BIM) process. Our goal was to bring digital tools into the construction phase to influence the following:

- A digital control tower brings together owner representatives, the lead contractor, and subcontractors to discuss plans and track progress around one common source of truth, with an integrated master schedule.

- Tracking and forecasting. Using drones as well as fixed and hand-held scanners, frequent 3D site scans linked to the BIM model can automatically detect deviations, forecast potential clashes in constructability or work-package execution, and ultimately feed into the reporting dashboards of the digital control tower.

- Worker safety and material workflows. Sensor-based safety technology fosters a safer and more focused on-site work environment, helping workers follow safety protocols more closely and remain aware of their surroundings.

First steps toward fully digital construction

Pushing technology frontiers is less important to success in digital construction than a shared commitment to changing the approach. Most architects and engineers today work in BIM, but finding other critical partners with experience in or who are open to other new solutions as part of a fully digital construction model can be complicated.

In our initial discussions, contractors expressed great curiosity about the applications of digital tools. In particular, executing contractors worried that a rollout of digital tools might actually create more work, especially at the beginning of the effort. This initial hesitance was not unwarranted the 3D site scans, digital tracking tools, and sensor equipment for workers all had to be budgeted for, and some foundational work, such as creating a more meticulous schedule, had yet to be completed.

Indeed, before putting these digital tools to work, we needed not only to champion tangible, granular data but also to reset the general understanding of collaboration. The digital control tower is intended to facilitate this new way of working among parties shifting from reporting only on specific milestones to routine, almost real-time reporting that allows for ad hoc problem solving.

More important, we have learned that walking toward rollout together is essential for building trust in the tools. Digital tools create value not by reinforcing old mechanisms, where the project owner exerts control and contractors struggle to deliver, but by serving as catalysts to a joint understanding, joint truths, and joint success.

For example, by collaborating on schedule granularity and quality, our owners and contractors established physical key performance indicators (KPIs) to guide the project such as the volume of concrete that had been poured or the area of semi-precast slabs that had been installed, both of which could be found in the scans. Monitoring this activity in almost real time enabled daily tracking. The significant effort paid off in multiple ways. For example, it increased the owner’s understanding of what needed to be done, where to expect bottlenecks, and the challenges facing contractors (which were sometimes as simple as making sure ensuring an adequate workforce was available on a holiday). The effort also yielded immediate performance improvements for instance, better visibility allowed us to resequence activities and reclaim several weeks of delay due to COVID-19 shutdowns.

Keeping ambition high—what’s next

We are still at the beginning of our digital-construction journey, but the benefits of using digital tools have already outweighed the added up-front cost.

Thinking ahead, we want to better link our tools and enhance our analytics. We are striving, for instance, for fully automated progress reporting that links the performance KPIs embedded in the digital control tower with the evaluation of the 3D scans against the BIM model. We also want to optimize our integrated master schedule so that all parties benefit from improved activity sequencing, earlier alerts on required worker mobilization, real-time knowledge of timing and logistics (for both off- and on-site materials), and safer working conditions.

And we are keen to train additional subcontractors as they come on site to ensure they have a consistent level of capabilities and continuously foster a shared understanding of this new way of working.

McKinsey